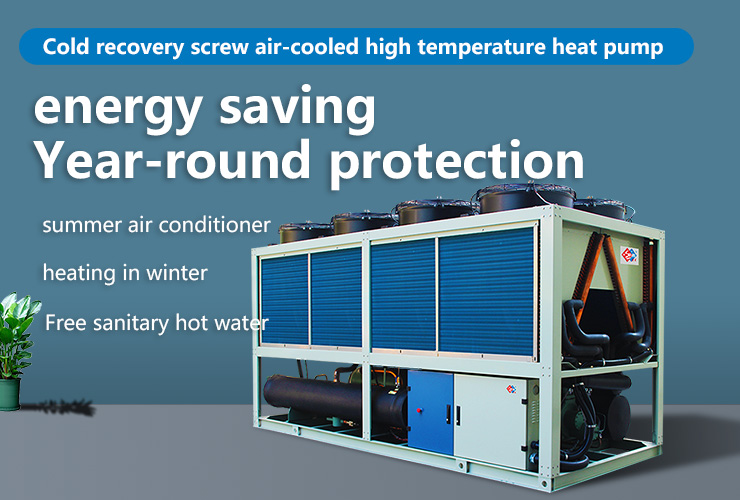

Air conditioning

- Outlet temperature

- 5~20℃/45~55℃

- Refrigerant

- R22、R134a

- Cooling range

- 27kw-416kw

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

Evaporative condensers integrate cooling towers, condensers, circulating water pools, circulating water pumps and water pipes, reducing the cost of handling and installing individual components in the cooling tower/condenser system.

Since the evaporative condenser utilizes the evaporative cooling heat exchange method with high energy efficiency, it can effectively reduce the heat exchange area, the number of fans and the power consumption of the fan motor.

There is no need for a dedicated computer room, reducing the cost of civil construction investment.

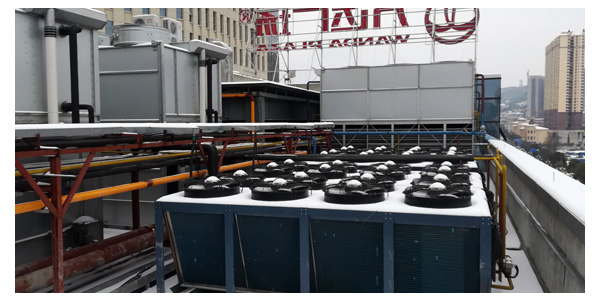

The compressor power saves at least 10% power consumption compared with other cooling tower/condenser systems, and saves 30% power consumption compared with the air cooling condenser system, and the fan power is similar to the cooling tower/condenser system The fan consumes the same power and is about one-third of the power of the fan of the same size air cooling condenser.

Due to the lower pump head and reduced water flow, the pump power is approximately twenty-five percent of that required in a typical cooling tower/condenser system.

Evaporative condensers save valuable space by integrating the condenser coil and cooling tower, and eliminate the need for the larger pumps and piping required for cooling tower/condenser systems.

Evaporative condensers only require about 50 percent of the windward area of an air cooling condenser of the same size.

Low water consumption (3~5% of water cooling condenser) and small air flow.

The outdoor evaporator of the dual-source heat pump unit adopts an air cooling fin evaporator, and the air is used as the heat source for heating in winter. Compared with the ground source heat pump system, the investment cost is greatly reduced.

The unit is multi-purpose, cooling in summer and heating in winter.

| model | Cooling capacity | Heating capacity | weight | Refrigerant |

| 40STD-420SHS4 | 383kw | 330kw | 7340kg | R22 |

| 40STD-700SHS4 | 634kw | 550kw | 10820kg | R22 |

| 40STD-1000SHS4 | 898kw | 770kw | 14500kg | R22 |

| 40STD-1860SHS4 | 1697kw | 1450kw | 2150kg | R22 |

| ... | ||||

| Note: Only some model parameters are shown. For more model information, please contact customer serviceEmail:maychow@hstars.com.cn | ||||

It is aimed at the explosion-proof needs of special places with flammable and explosive in the petroleum, chemical industry, coal mining industry and so on. The unit can be specially designed according to different explosion-proof grades, and the explosion-proof grade can reach: Ex dIIBT4. And provide explosion-proof certificate.

Provide professional solutions for anti-corrosion media such as sewage source, sea water source, waste gas, and waste water in the application site.

For different cases, provide professional solutions, energy saving, high energy efficiency, environmental protection and durability.

Flexible configuration of spare parts brands, professional technology, modular replacement, and strict control of details.

Special chillers with ultra-high temperature effluent and ultra-low temperature effluent can be specially designed according to the place where the equipment is used, the scene of application, and the process requirements.

Remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance.

Chat now