Heat Recovery In

Has a patent for heat recovery (profit number: ZL03223588.7). The wast

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

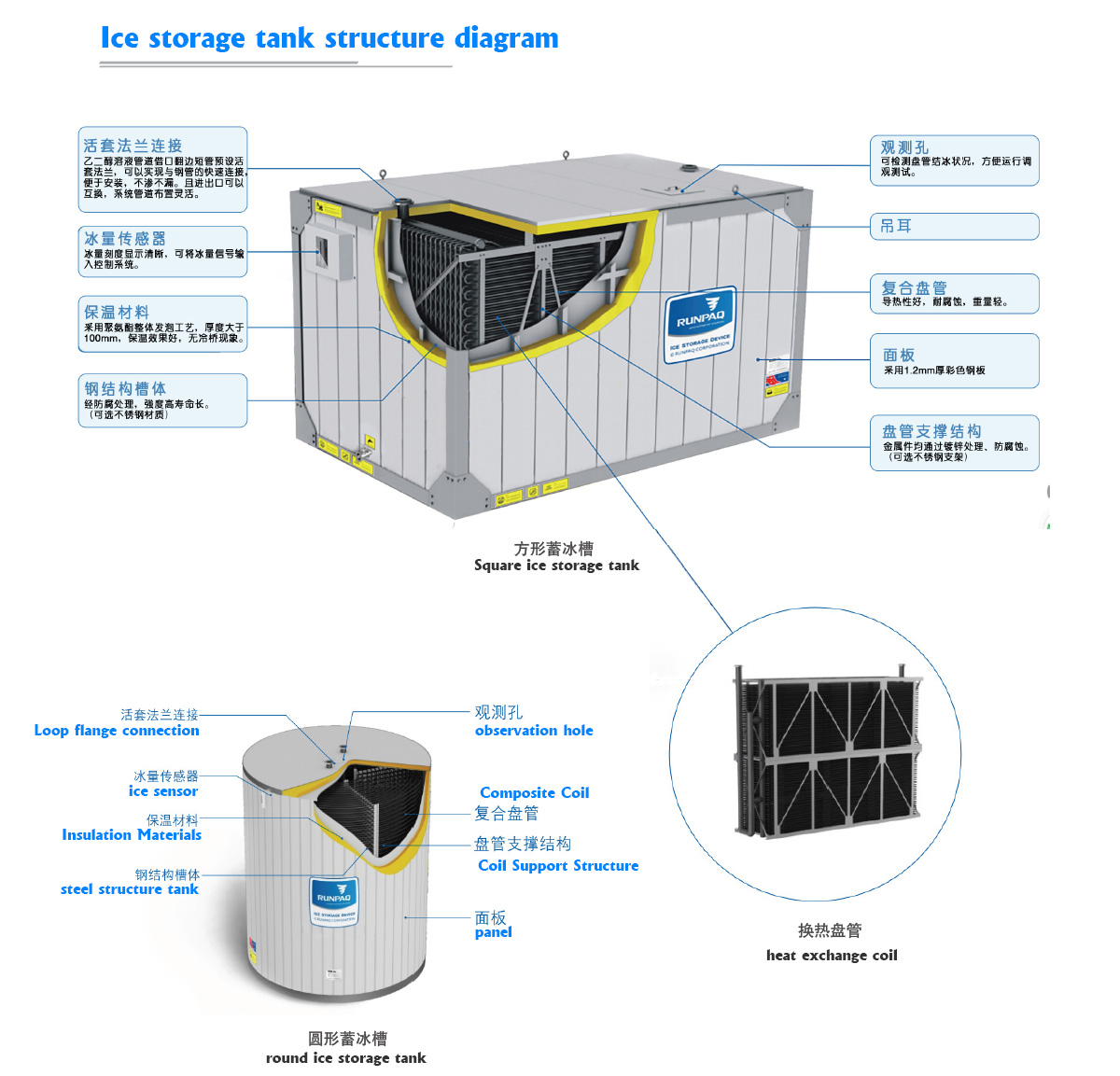

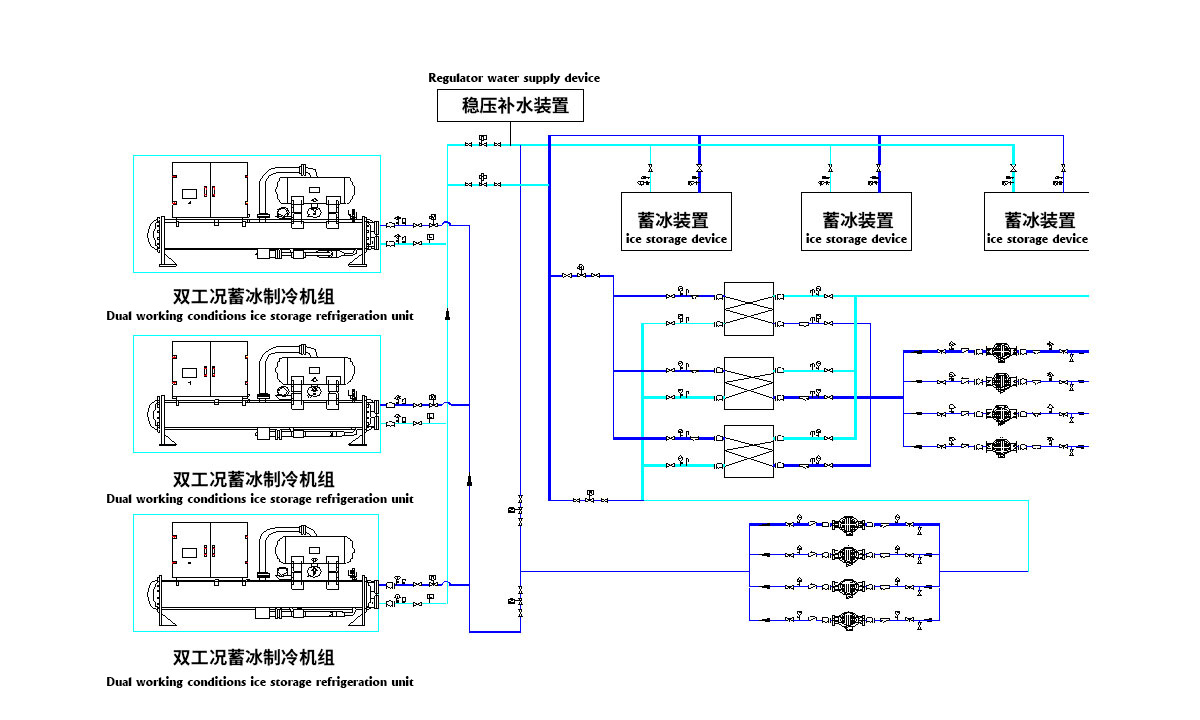

The ice storage technology is to store cold energy in the form of ice inside the ice storage device through the refrigeration equipment when the electricity price is low at night, and melt the ice into low-temperature water for cooling demand during the peak electricity consumption during the day.

Using the peak-valley electricity price difference to reduce the operating cost of air conditioners, it can also be applied to multi-purpose special technologies such as industrial refrigeration process water, improving air conditioner quality, and reducing installed capacity.

Ice storage system function

○The regional power supply policy is used to achieve "moving peaks and filling valleys", making ice when the electricity price is low at night, and melting the ice for cooling when the electricity price peaks during the day.

○Reduce installed capacity and supporting facilities, and reduce investment in power distribution projects.

○The dual-mode refrigeration unit is used to realize the air-conditioning and ice-making conditions, and one machine can be used for two purposes.

○Emergency function: ice storage in the ice tank keeps the cooling supply constant, effectively solves the loss of supply and production shutdown caused by unit failure, and ensures the safety of use due to system failure.

○The ice storage system can provide 1-4°C constant low temperature water supply to achieve large temperature difference cooling.

○It is suitable for areas where the peak-to-valley electricity price is greater than or equal to 2.5:1, cooling demand and process demand.

○It is suitable for the needs of limited grid supply and cost control.

○Use in places that require ice storage refrigeration and air conditioning and industrial refrigeration projects.

○For important production processes, production lines, refrigerated warehouses and important office spaces, it can reduce the investment of spare equipment.

○Suitable for precision equipment cooling, food industry, milk technology and other industries.

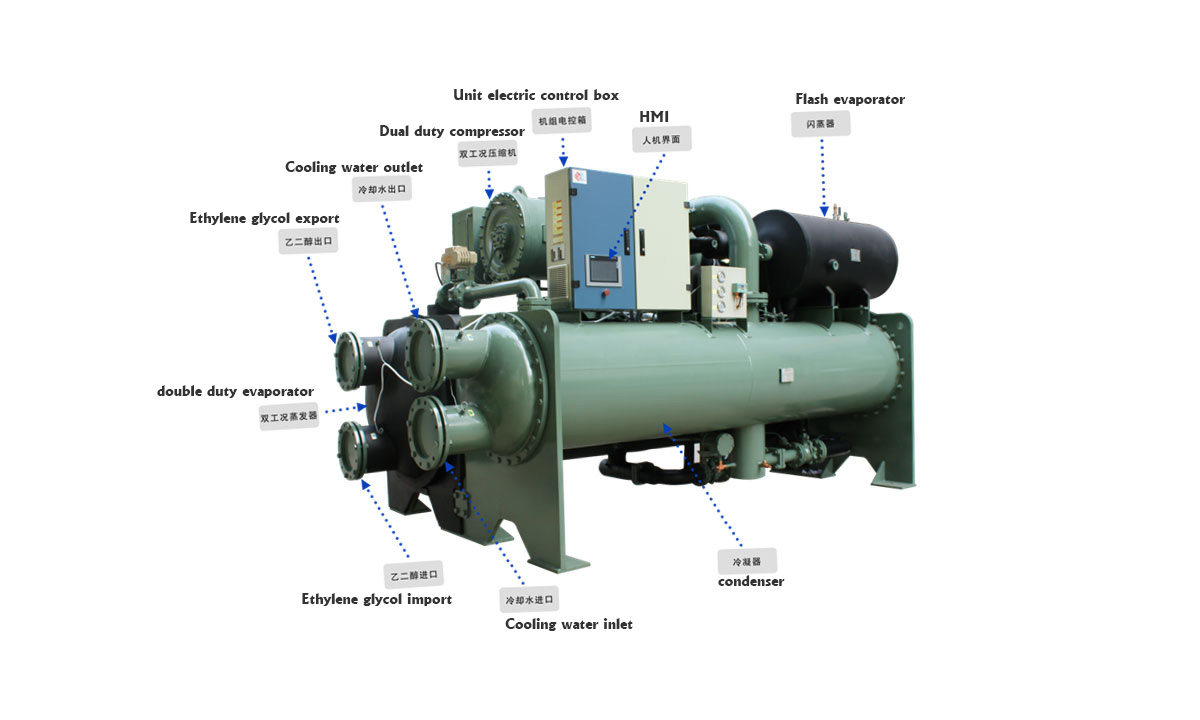

1. When the electricity price is low, the ice storage refrigeration unit with dual working conditions will operate according to the ice storage condition.

2. The glycol pump transports the cooling capacity of the refrigeration unit to the ice storage device

3. The ice storage device absorbs the cooling capacity of the refrigeration unit, converts water into ice and stores it in the ice storage device

4. When the electricity price peaks, the ice storage refrigeration unit with dual working conditions will be shut down

5. The ethylene glycol pump transports the cold energy stored in the ice storage device to the plate exchange for heat exchange

6. The ice storage device converts the stored ice into water and releases cold energy

It is aimed at the explosion-proof needs of special places with flammable and explosive in the petroleum, chemical industry, coal mining industry and so on. The unit can be specially designed according to different explosion-proof grades, and the explosion-proof grade can reach: Ex dIIBT4. And provide explosion-proof certificate.

Provide professional solutions for anti-corrosion media such as sewage source, sea water source, waste gas, and waste water in the application site.

For different cases, provide professional solutions, energy saving, high energy efficiency, environmental protection and durability.

Flexible configuration of spare parts brands, professional technology, modular replacement, and strict control of details.

Special chillers with ultra-high temperature effluent and ultra-low temperature effluent can be specially designed according to the place where the equipment is used, the scene of application, and the process requirements.

Remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance.

Has a patent for heat recovery (profit number: ZL03223588.7). The wast

The frequency conversion centrifugal unit is based on the existing uni

Using high-efficiency flooded evaporator and evaporative condenser, th

The two devices adopt the American ASME standard and meet the ASME req

Chat now