Dehumidification

Hongxing heat pump drying unit is a hot air drying product independent

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

•Air energy drying equipment, integrating drying and dehumidification, multi-purpose

•All-in-one design, integrated function, custom setting function

•Built-in heat recovery function to recycle heat energy

•Environmental protection, no pollution, safety and no risk

•Design life 15+ years

•COP 2.8+, 4 times the energy efficiency of electric boilers

•Automated operation without human management

•Combined structure, easy to install and dismantle

•This equipment is not affected by the ambient temperature and is suitable for the north and south regions.

•Not affected by bad weather such as overcast, rain and snow.

•Intelligent control, fully automatic operation, no need to be on duty.

•One-key start mode, no tedious operation is required.

| Dehumidification function | Hybrid function | Dehumidification function |

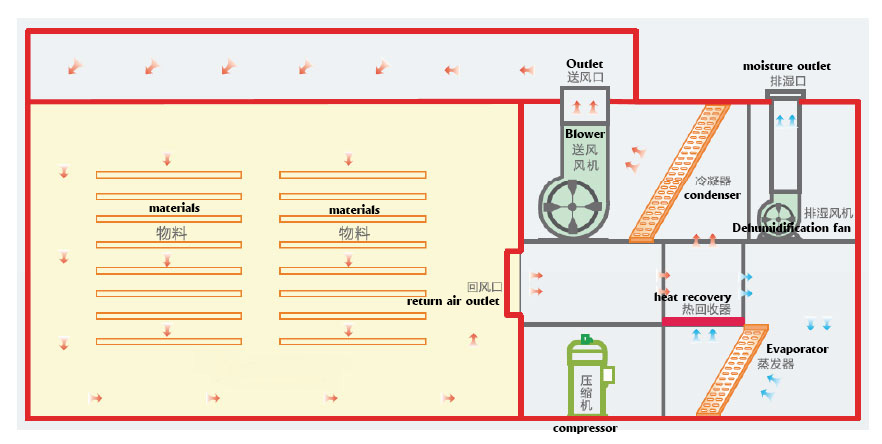

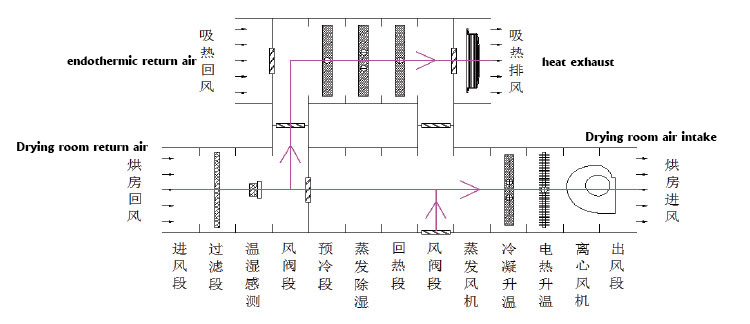

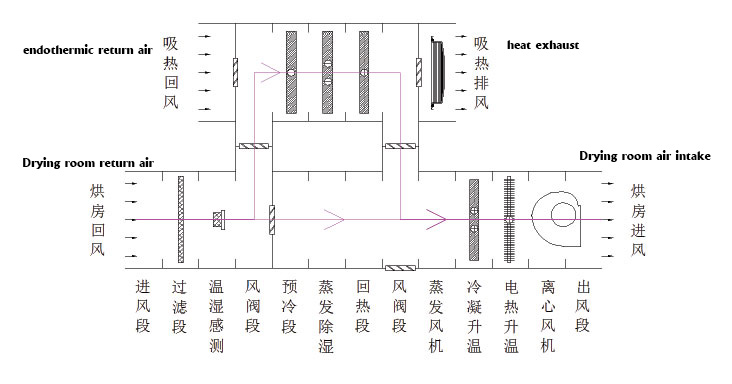

| The heat pump host generates high-temperature hot air by absorbing the energy in the air, which is sent to the drying board room, thereby generating water vapor through the high-temperature hot air, and then sending the water vapor away through an outlet of the board room. | Intelligent switching of open-loop dehumidification and closed-loop dehumidification and drying methods, sensible heat, latent heat recovery system, avoid low heating efficiency in low temperature environment, fresh air purification system, effectively discharge dust, sundries and grease out of the drying space to better retain the inside of the oven temperature. | The air in the drying room is heated repeatedly in a cycle to absorb the moisture in the material. The heat pump evaporator absorbs the latent heat of the condenser while dehumidifying, and provides heat energy for the temperature rise. The repeated cycle realizes the drying of the material. |

| model | Dehumidification(kg/h) | Moisture removal(kg/h) | Refrigerant | weight kg |

| 20STB-M06AGS4 | 26 | 18 | R134a | 850 |

| 20STB-M08AGS4 | 35 | 24 | R134a | 1050 |

| 20STB-M10AGS4 | 43 | 30 | R134a | 1250 |

| 20STB-06AGS4 | 34kw | 23kw | R22 | 850 |

| 20STB-08AGS4 | 45kw | 31kw | R22 | 1050 |

| 20STB-10AGS4 | 57kw | 38kw | R22 | 1250 |

| ... | ||||

| Note: Only some model parameters are shown. For more model information, please contact customer serviceEmail:maychow@hstars.com.cn | ||||

1. Multifunctional drying: The unit has four functions: heating, dehumidification, dehumidification and automatic.

2. High efficiency and energy saving. The heat of heating the air in the heat pump dryer mainly comes from the sensible heat and latent heat contained in the warm and humid air discharged from the recovery drying room. The energy that needs to be input is only the power consumption of the heat pump compressor, and the heat pump can consume a small amount of work Taking advantage of a large amount of heat, the SMER (the amount of moisture in the wet material removed by the unit energy consumed) of the heat pump drying device is usually 1.0 ~ 4.0kg/kWh, while the SMER value of the traditional convection dryer is about 0.2 ~ 0.6kg/kWh.

3. Precise control of temperature and humidity: when the material has high requirements on the temperature and humidity of the air entering the drying room, the evaporating temperature and condensation temperature of the working fluid in the evaporator and condenser can be adjusted to meet the texture and appearance of the material. and other requirements.

4. Recovery of useful volatile components: some materials contain volatile components (such as fragrance), when using heat pump drying, in the drying room, volatile components and moisture are vaporized into the air together, and the air containing volatile components When the evaporator is cooled, the volatile components in it are also liquefied and discharged together with the condensed water, collect the condensed water containing the volatile components, and separate the useful volatile components by an appropriate method.

5. Environmental protection and pollution-free: the drying medium in the heat pump drying device is in a closed cycle, and there is no pollution caused by material dust, volatile substances and odors discharged to the environment with the drying exhaust gas; the waste heat in the exhaust gas of the drying chamber is directly recovered by the heat pump To heat the cold and dry air, there is no thermal pollution of the unit to the environment.

6. Low temperature drying: By controlling the working conditions of the device, the temperature of the hot dry air in the drying chamber is between 20 and 80 °C, which can meet the high-quality drying requirements of most heat-sensitive materials; the closed cycle of the drying medium can avoid Impurity contamination that may be brought to the material by the exchange with the external gas, which is especially important for food, medicine or biological products.

7. Drying of flammable materials: When the material is sensitive to oxygen in the air (easy to oxidize or burn and explode), an inert medium can be used instead of air as the drying medium to achieve anaerobic drying.

8. The heat pump dryer is suitable for a wide range of materials. The materials suitable for drying are mainly materials that can withstand temperatures between 20 and 80 °C during the drying process, or materials that can withstand higher temperatures but are more energy-efficient or safe to use heat pump drying. Materials that have been researched and applied more, such as wood, grains, seeds, edible fungi, medicinal materials, seafood, biologically active products, tea, paper, etc.

9. Compared with other low-temperature (air temperature in the drying chamber < 40℃) drying devices (such as microwave drying, vacuum drying, freeze drying), due to the small initial investment of equipment and low operating costs, the heat pump dryer device has obvious advantages. economical. The equipment cost of the heat pump drying device is mainly the heat pump part and the drying chamber part, of which the drying chamber part has the same requirements as the ordinary convection drying chamber, and there is no special air tightness and pressure bearing requirements.

10. Compared with ordinary drying devices (air temperature in the drying room > 40 °C), the initial investment of heat pump dryers is generally higher than that of electric air heating devices, gas or coal-fired hot blast stoves, and the initial investment of drying devices is generally higher. Compared with ordinary drying devices, heat pump dryer drying devices have high energy efficiency, low operating costs, and still have certain advantages in overall economy.

The drying room insulation room is made of polyurethane rigid foaming process. Using the principle of rolling barrels, the metal plate is placed on a specially designed plate feeding belt, and the polyurethane foaming agent is sprayed on the metal plate by a spraying device. After high temperature treatment The foaming agent is foamed between the metal plates to complete the three-layer one-time integrated polyurethane (PU, PIR) metal sandwich panel.

Polyurethane is currently internationally recognized as the best thermal insulation material. It has low thermal conductivity, good load resistance, high flexural strength, no water absorption, no decay, no moth and rat bite, good flame retardancy and large temperature resistance range. The heat transfer due to the temperature difference between inside and outside can be reduced to achieve greater efficiency of the drying system.

Optional foam thickness:60、75、100、120、150、180、200mm。

Metal plate specifications are optional: embossed aluminum plate, stainless steel plate, color zinc steel plate, salted steel plate, galvanized plate.

It is aimed at the explosion-proof needs of special places with flammable and explosive in the petroleum, chemical industry, coal mining industry and so on. The unit can be specially designed according to different explosion-proof grades, and the explosion-proof grade can reach: Ex dIIBT4. And provide explosion-proof certificate.

Provide professional solutions for anti-corrosion media such as sewage source, sea water source, waste gas, and waste water in the application site.

For different cases, provide professional solutions, energy saving, high energy efficiency, environmental protection and durability.

Flexible configuration of spare parts brands, professional technology, modular replacement, and strict control of details.

Special chillers with ultra-high temperature effluent and ultra-low temperature effluent can be specially designed according to the place where the equipment is used, the scene of application, and the process requirements.

Remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance.

Chat now