Combined cooling

- Outlet temperature

- 5~20℃/45-50℃

- Refrigerant

- R22/R134A

- Cooling range

- 350KW-950KW

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

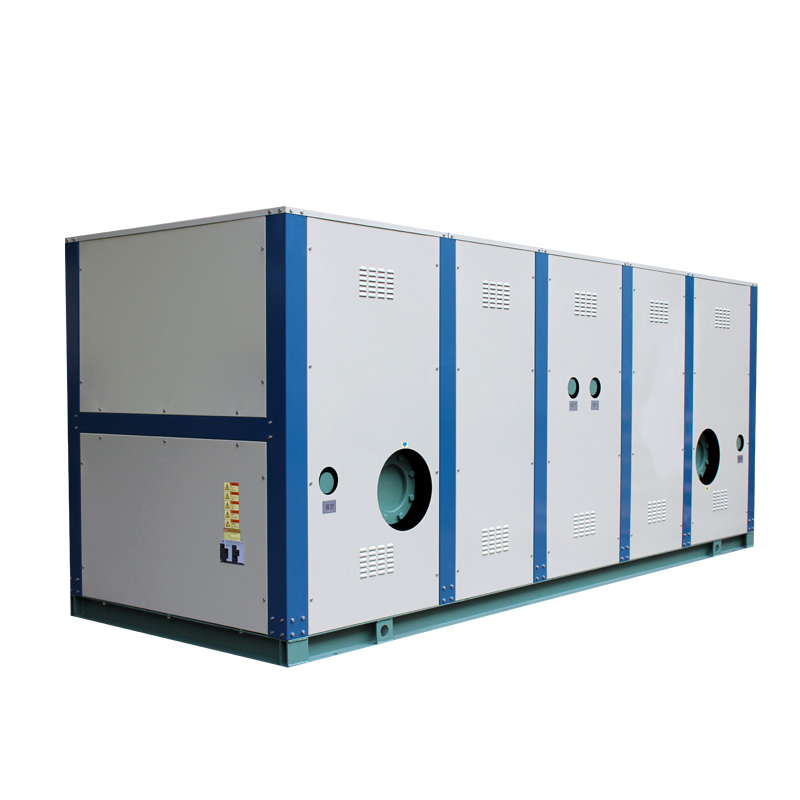

The two-stage centrifugal compressor is not easy to surge; the system economizer supplies air between the compressor stages, and the cooling capacity is increased by at least 10%.

Intelligently judge the surge area, adjust the speed and IGV in time, avoid the occurrence of surge, and make the operation more stable and safer.

Gear speed-increasing drive, the impeller volume is smaller, the motor starting torque is small, and the downtime is short.

The motor is integrated with the compressor, and the running noise is low, and there is no risk of leakage.

The motor is cooled by liquid refrigerant, with low operating temperature and high efficiency.

Use high-strength ball/roller bearings, not afraid of compressor emergency stop.

Using an independent oil return system (ejection pump oil return), it can ensure timely oil return under any load conditions.

The unit has built-in oil cooler, which is cooled by refrigerant, which is safe and reliable.

The oil pump is built into the compressor oil sump, eliminating the risk of oil pump leakage.

The use of self-developed and produced high-efficiency spray heat exchangers, and the use of precise liquid level control technology, ensures that the evaporator is always in a high-efficiency heat exchange state.

The condenser adopts droplet separation technology to ensure high energy efficiency and sufficient heat exchange of the condensing heat exchange tube.

COP value up to 6.3

Using self-developed heat recovery device, the waste heat generated in the refrigeration process is recovered. While providing customers with cold water, a large amount of hot water can also be supplied free of charge.

The mainstream environmentally friendly refrigerant R134a is used, which has good comprehensive performance, and the ozone depletion value (ODP) is 0.

The self-developed multi-stage throttling device has an adaptive function. When the load changes and the working conditions change, the refrigerant supply can be adjusted in time without lag, ensuring that the unit is in a state of high energy efficiency at any time.

The fully automatic microcomputer touch control system is adopted to clearly display various operating data and timely feedback various maintenance information, without the need for full-time operators. The unit control system can be connected to the user's central control system, so that the unit operation can be fully understood at any time.

| model | Cooling capacity | Heating capacity | weight | Refrigerant |

| 50STD-600H2 | 2360kw | 2280kw | 10100kg | R134a |

| 50STD-900H2 | 3368kw | 3280kw | 12500kg | R134a |

| 50STD-1200H2 | 4653kw | 4500kw | 15500kg | R134a |

| 50STD-1800H2 | 6736kw | 6560kw | 23000kg | R134a |

| ... | ||||

| Note: Only some model parameters are shown. For more model information, please contact customer serviceEmail:maychow@hstars.com.cn | ||||

It is aimed at the explosion-proof needs of special places with flammable and explosive in the petroleum, chemical industry, coal mining industry and so on. The unit can be specially designed according to different explosion-proof grades, and the explosion-proof grade can reach: Ex dIIBT4. And provide explosion-proof certificate.

Provide professional solutions for anti-corrosion media such as sewage source, sea water source, waste gas, and waste water in the application site.

For different cases, provide professional solutions, energy saving, high energy efficiency, environmental protection and durability.

Flexible configuration of spare parts brands, professional technology, modular replacement, and strict control of details.

Special chillers with ultra-high temperature effluent and ultra-low temperature effluent can be specially designed according to the place where the equipment is used, the scene of application, and the process requirements.

Remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance.

Chat now