Small and medium

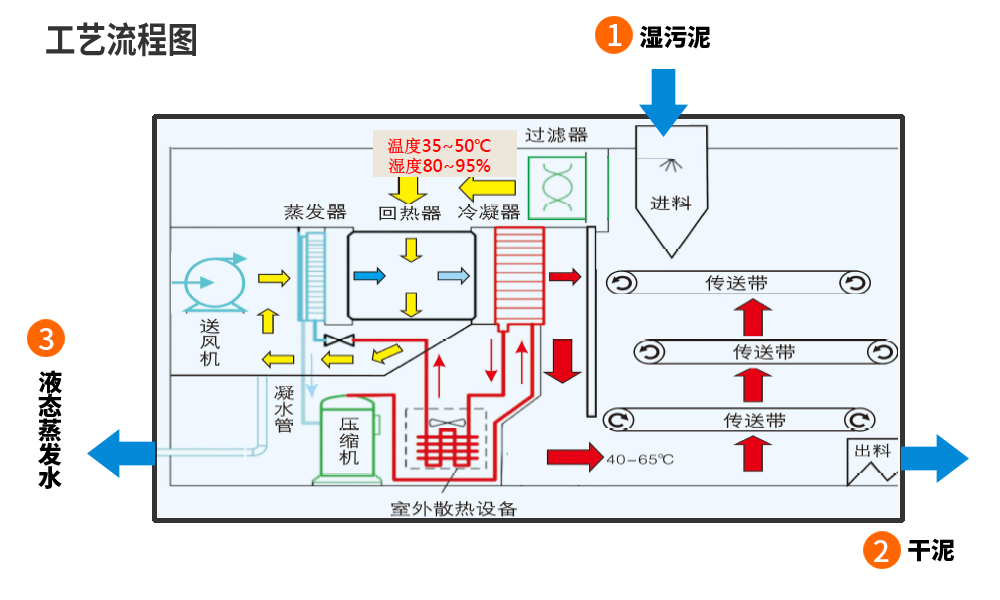

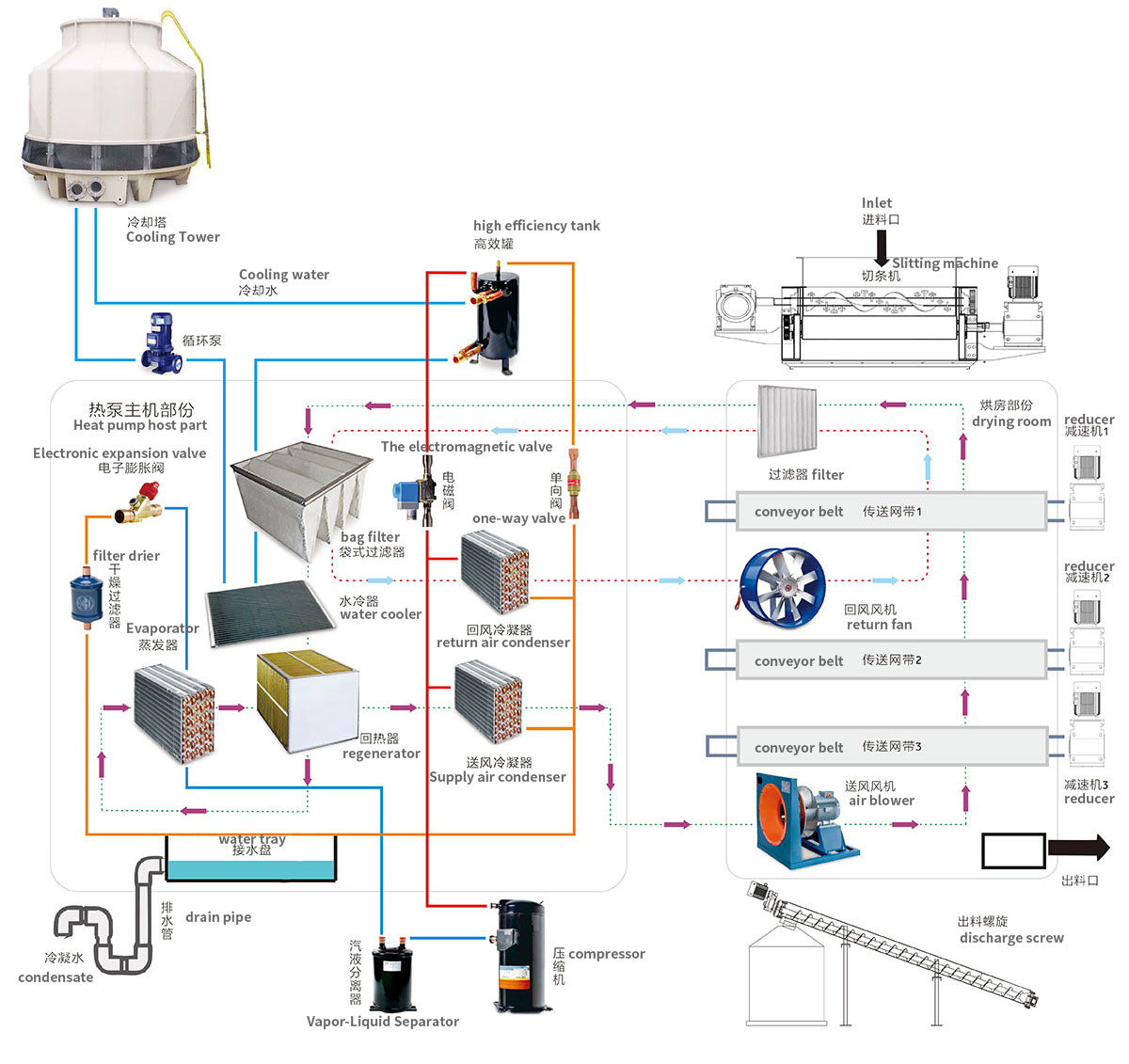

Through the combined action of high temperature heat source and dehumi

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

The cost is about 200-250 yuan / ton. The power consumption is lower than that of the same type of industry, and the water removal rate is also higher than that of the same type of industry.

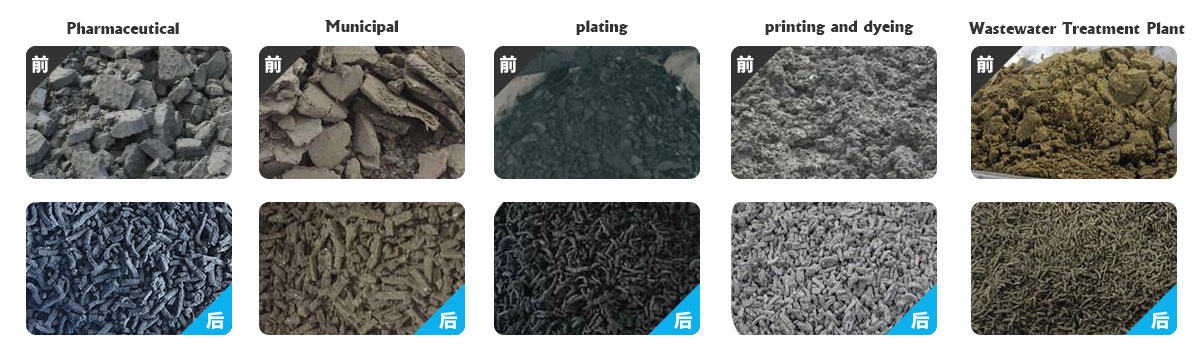

Strong drying ability, intelligently control the water content of the mud, and automatically and accurately adjust between 10-40%.

Fully automatic integrated design, easy safety and maintenance. Improve economic efficiency, but also achieve timely and accurate reflection.

Low temperature dehumidification technology, humidity gradient, mass transfer, small air volume, less dust.

Closed circulation system, zero emission, no odor, not affected by external climate. No harm to the natural environment.

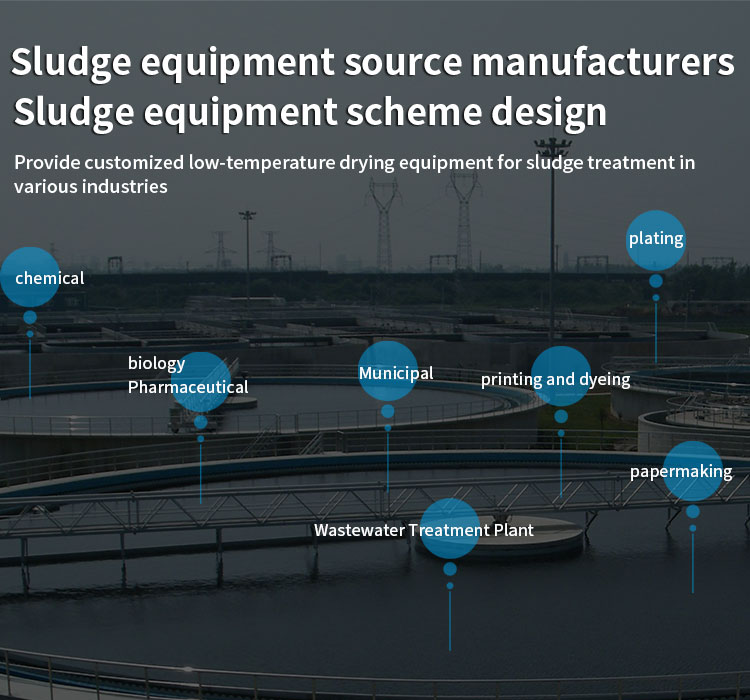

Professional anti-corrosion design, can be customized, suitable for sludge drying and reduction in different industries.

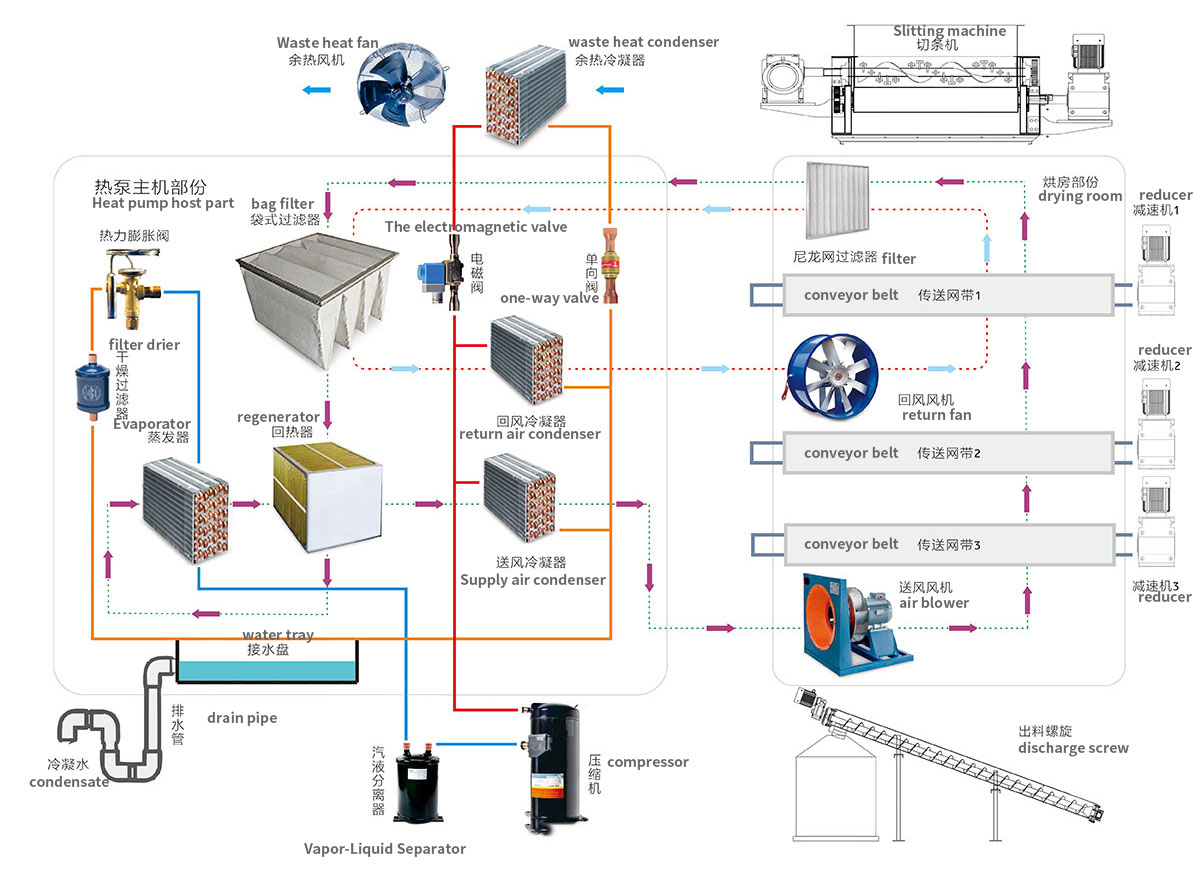

The unit uses the company's five core technologies: humidity gradient, uniform air flow in the drying room, countercurrent drying, fully enclosed independent air duct, and nano-electrophoresis anti-corrosion technology for heat exchangers. The comprehensive effect of the five core technologies is remarkable, the unit is low temperature energy saving, small air volume, fast drying, and the overall unit energy efficiency can be as high as 4.0 or more. The compressor adopts an internationally renowned brand of fully enclosed heat pump dedicated scroll compressor. The whole machine is a standard modular design, with a small footprint and flexible installation.

1Simple equipment, automatic control

2Low temperature system, high efficiency and energy saving

3Small air volume, no dust

4Equipment integration, easy installation

5Durable material and easy maintenance

6Closed system, no odor emission

| project | A new generation of low temperature closed cycle sludge drying equipment | traditional heat pump drying | traditional heat drying |

| Drying principle | Humidity Gradient, Drainage Technology | surface evaporation | heating evaporation |

| drying temperature | 40-65°c | 70-80°c | 150-500°c |

| Evaporation cost per ton | 200-250 yuan | 260-300 yuan | 500-750 yuan |

| heat absorption mode | total heat absorption | partial heat absorption | partial heat absorption |

| Main machine thermal energy efficiency | 400%~ | 250% | 40%-60% |

| Evaporated water per kilowatt-hour | 3.5-4.0kg | 2.5-3.0kg | 1-1.5kg |

| Traditional heat pump dryer | Low temperature dehumidification and drying unit | relative advantage | |

| Sludge moisture conten | 70%~90%(20%) | 40%~90%(50%) | Substances that do not need to sacrifice the low cost of the filter press to remove water |

| drying temperature | 70°c~80°c | 40°c~60°c | Heat pump heating and water removal efficiency improvement15% |

| water removal capacity | 2~3Kg water/kWh | 3~4Kgwater/kWh | Comprehensive energy saving improvement20~40% |

| model | unit | JKFY-4800 | JKFY-9600 | JKFY-14400 | JKFY-19200 | JKFY-24000 |

| drying temperature | ℃ | 40~85℃ | ||||

| Rated water removal | kg/24h | 4800 | 9600 | 14400 | 19200 | 24000 |

| Rated water removal | kg/h | 200 | 400 | 600 | 800 | 1000 |

| Hot water in/out temperature | ℃ | 90/70 | ||||

| Cooling water inlet/outlet temperature | ℃ | 32/37 | ||||

| heat source | Hot water, saturated steam, high temperature flue gas and other waste heat | |||||

| hot water load | kW | 160 | 320 | 480 | 640 | 800 |

| hot water flow | m³/h | 7 | 14 | 21 | 28 | 35 |

| cooling tower cooling load | kW | 190 | 380 | 570 | 760 | 950 |

| Cooling water flowΔt=5℃ | m³/h | 33 | 66 | 99 | 132 | 165 |

| rated power | KW | 16 | 32 | 48 | 64 | 80 |

| Distribution capacity | kW | 20 | 40 | 60 | 80 | 100 |

| Dehumidification energy consumption | KG/kW·h | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

| Dimensions (L*W*H) (without conveying system) | mm | 5470×2950×3000 | 9290×2950×3000 | 13110×2950×3000 | 16930×2950×3000 | 20750×2950×3000 |

| weight | kg | 6740 | 12460 | 17820 | 23360 | 28900 |

Note: 1. Standard water removal tons: the water content of the mud is 65%, and the water content of the mud is 25%, the water tons that can be removed; ★Due to different sludge properties and different water content, the drying cycle is different. deviation.

Chat now