get up this morning

Do you guys think

cold ~ air ~ forcing ~ people

lowly worker

Hurry up and add some more clothes

so warm this winter

but

According to reliable sources

There will also be a cooling process

Antifreeze, cold, cold

adult child clothes

Measures for fruits and vegetables

What measures should be taken to prevent frost damage to crops?

everyone will do

Reinforced coverage to keep warm and antifreeze

Fertilize the soil to increase the soil temperature

Nitrogen control and ash to improve cold resistance

Timely irrigation to ensure the smooth flow of ditches

Fertilize and cultivate soil, antifreeze and protect seedlings

Timely irrigation to increase soil temperature

But the result is that it is found that some vegetables will inevitably suffer from freezing damage during the winter, and it is difficult to resist the cold current, and crops will suffer from freezing damage, resulting in economic losses.

Now

it's coming

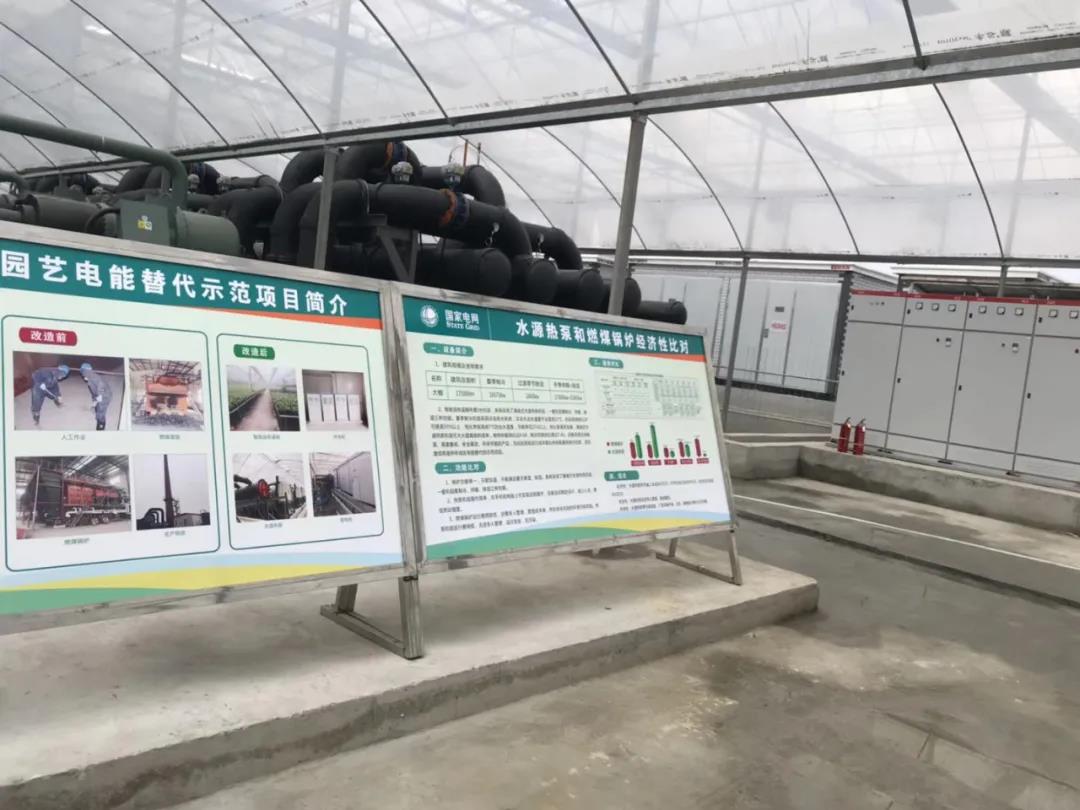

my country has introduced relevant policies to encourage farmers to use heat pump heating for clean heating, promote energy conservation and emission reduction, and contribute to carbon neutrality. However, with the application of new heating equipment, the cost of growing greenhouses has increased, which has caused many economic difficulties to many vegetable farmers who are planning to build greenhouses or have already started to build greenhouses. Because we walked into a misunderstanding and lacked professional guidance;

In this regard, the editor tells you that in the greenhouse, improving the heating equipment is one of the measures for advanced technology to enter the greenhouse for planting, and it is also the focus of determining the cost of breeding. The company has set up a special R&D team to provide excellent solutions to solve problems for vegetable farmers; therefore, everyone must overcome various difficulties, take the road of new technology-based agricultural industry, and build low-consumption, high-yield agricultural parks; while enjoying the policy Dividends also contribute to accelerating the green and low-carbon development of my country's economy and society.

The following editor will introduce to you the transformation project of the nursery greenhouse, including the transformation of the main body of the greenhouse, the addition of thermal insulation equipment, and the transformation of the heating system.

Project Overview

A planting area in northern my country is mainly used to grow high-grade bonsai and flowers. Currently, a 175,000-square-meter planting base is being built. Due to the particularity of planting, plants have different requirements for air temperature and humidity in different time periods. We need to heat or cool the greenhouse to ensure normal growth of plants in bad weather.

client needs

1. The indoor temperature of the greenhouse in summer is 30±2℃, and the indoor temperature in winter is 20±2℃;

2. The relative humidity in the greenhouse in summer and winter is 70%~75%;

3. The equipment is used as backup for each other to ensure trouble-free operation throughout the year;

4. Energy saving, water saving, land saving and environmental protection;

5. Intelligent control and mobile phone cloud operation function;

solution

In view of the project needs and the climate conditions in the region, the Guangzhou H.Stars R&D team analyzed it, and focused on considering the customer from the three aspects of use safety, investment cost and operating cost, using the company's product advantages and manufacturing technology, in the spirit of energy saving and environmental protection. The purpose of the company is to provide it with a H.Stars water source heat pump solution: H.Stars high-efficiency water source heat pump unit + terminal system; to solve the effects of climate change, water temperature change and strong cold air on crops. Not only that, after the implementation of this plan, the park does not need special personnel to be on duty, and it can be easily managed and monitored at home even when it is snowing.

Features of equipment and solutions

Energy saving and high efficiency, saving operating costs: This project uses four flooded water source heat pump units, with a total cooling capacity of 14824KW and a total heating capacity of 15116KW, supplying 170,000 square meters of greenhouses. The cooling energy efficiency ratio of the unit reaches 7.02 and the heating energy efficiency ratio reaches 5.25, the water source heat pump consumes 1kW.h of electricity, and the user can get 4.3~5.0kW.h of heat or 5.4~6.2kW.h of cooling. It saves 30% to 80% energy than the general central air conditioner. It is one of the central air-conditioning systems with high efficiency and energy saving. The biggest feature of this project is that it adapts measures to local conditions and uses local groundwater resources to design a suitable system with high efficiency, energy saving and zero discharge.

One machine has multiple uses, saving initial investment: one set of equipment can realize cooling, heating, dehumidification and free production of a large amount of domestic hot water, one machine has multiple uses, and one system can replace the original two sets or systems of boiler and air conditioner, saving invest. The boiler room and auxiliary coal yard, oil storage room, cooling tower and other facilities are omitted. The area of the machine room is much smaller than that of the conventional air conditioning system, which saves the building space and is also beneficial to the beauty of the building.

Safe, reliable and easy to control: The constant temperature of the water body makes the operation of the water source heat pump unit more reliable and stable, ensuring the high efficiency and economy of the system, and does not require special personnel to maintain and operate, and the operation and maintenance costs are minimal. All air-conditioning systems are precisely controlled by microcomputers, and the main engine is connected to the circulation pump, submersible pump and other ancillary equipment. Users can charge independently, adjust water temperature, room temperature, start and stop time and remote monitoring.