Industrial integ

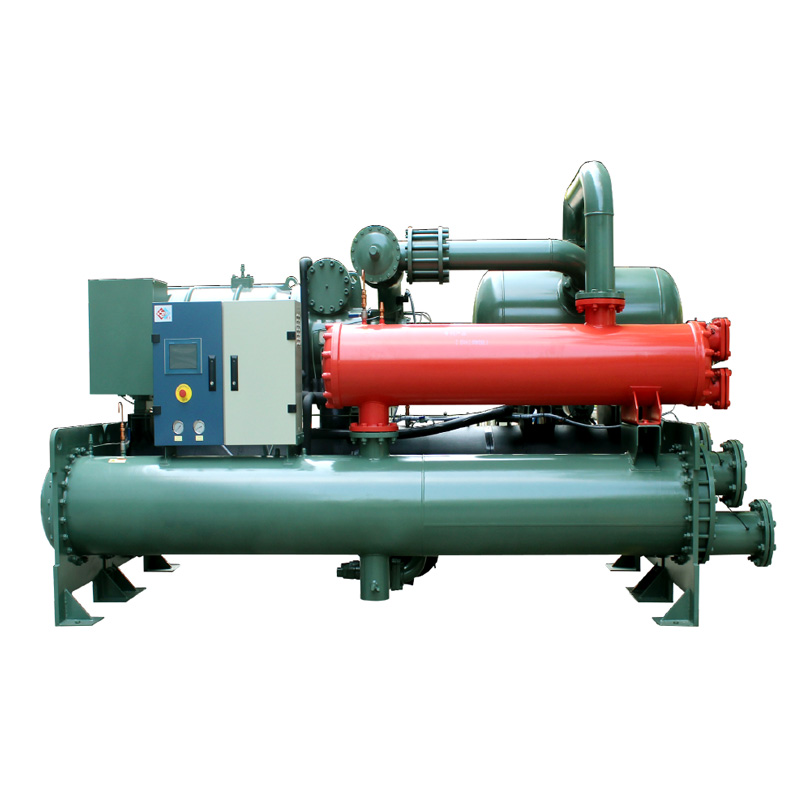

- Outlet temperature

- 5~20℃

- Refrigerant

- R22、R134a

- Cooling range

- 30kw~580kw

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

Two-stage centrifugal compressor, the system economizer supplies air between the compressor stages, and the cooling capacity is increased by at least 10%.

Intelligently determine the surge area, adjust the speed and IGV in time, avoid surge, and be more stable and safer than conventional centrifugal chillers.

High-speed permanent magnet synchronous motor with Refrigerant cooling, the efficiency is as high as 97%.

Built-in soft starter, the starting current is only 2A, no impact on the power grid.

The self-developed and produced high-efficiency heat exchanger is used, and the electronic expansion valve combined with the liquid level sensor is used to control the liquid level to ensure that the evaporator is always in a high-efficiency heat exchange state.

The IPLV was 10.7 and the partial load COP value was over 13.

Magnetic bearing, reduce energy consumption by 10%.

The system is oil-free, which reduces the heat exchange loss of the heat exchanger, improves the performance of the heat exchanger, eliminates the complicated oil circuit system, and is easy to maintain.

Has independent research and development of heat recovery technology. The waste heat generated during the refrigeration process is recovered using a technical heat recovery device. That is, while providing customers with cold water, a large amount of hot water can also be supplied free of charge.

Using the world's mainstream environmentally friendly refrigerant R134a, it has good comprehensive performance, and the ozone depletion value (ODP) is 0.

| model | input power | Cooling capacity | weight | Refrigerant |

| 50STD-150F2 | 95kw | 559kw | 2430kg | R134a |

| 50STD-300F2 | 190kw | 1117kw | 4600kg | R134a |

| 50STD-450F2 | 242kw | 1575kw | 11000kg | R134a |

| 50STD-900F2 | 484kw | 3150kw | 19000kg | R134a |

| 50STD-1350F2 | 726kw | 4725kw | 27000kg | R134a |

| 50STD-1800F2 | 968kw | 6300kw | 35000kg | R134a |

| 50STD-2250F2 | 1210kw | 7875kw | 43000kg | R134a |

| … | ||||

| Note: Only some model parameters are shown. For more model information, please contact customer serviceEmail:maychow@hstars.com.cn | ||||

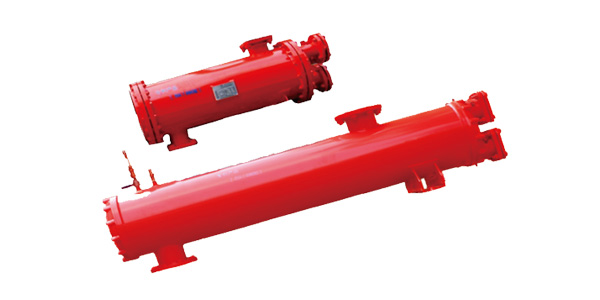

It is aimed at the explosion-proof needs of special places with flammable and explosive in the petroleum, chemical industry, coal mining industry and so on. The unit can be specially designed according to different explosion-proof grades, and the explosion-proof grade can reach: Ex dIIBT4. And provide explosion-proof certificate.

Provide professional solutions for anti-corrosion media such as sewage source, sea water source, waste gas, and waste water in the application site.

For different cases, provide professional solutions, energy saving, high energy efficiency, environmental protection and durability.

Flexible configuration of spare parts brands, professional technology, modular replacement, and strict control of details.

Special chillers with ultra-high temperature effluent and ultra-low temperature effluent can be specially designed according to the place where the equipment is used, the scene of application, and the process requirements.

Remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance.

Chat now