Industrial integ

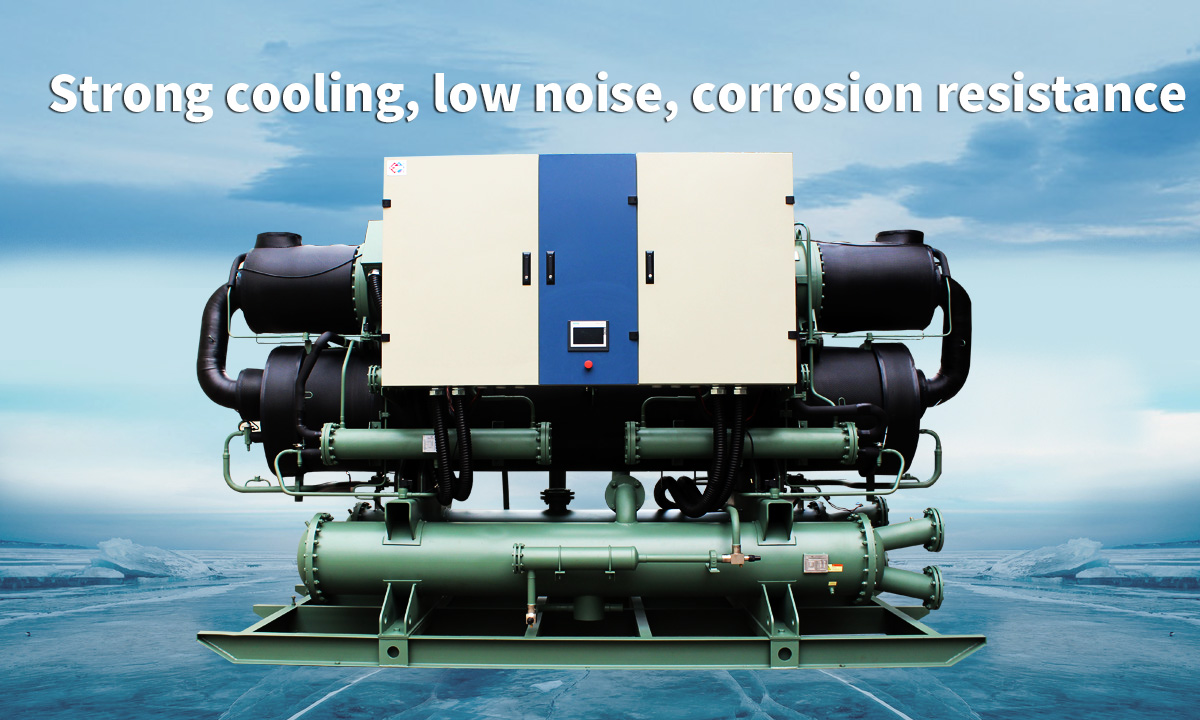

- Outlet temperature

- 5~20℃

- Refrigerant

- R22、R134a

- Cooling range

- 30kw~580kw

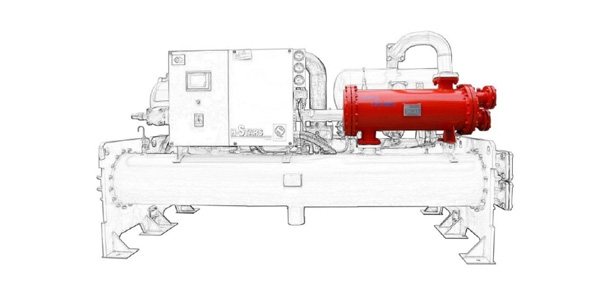

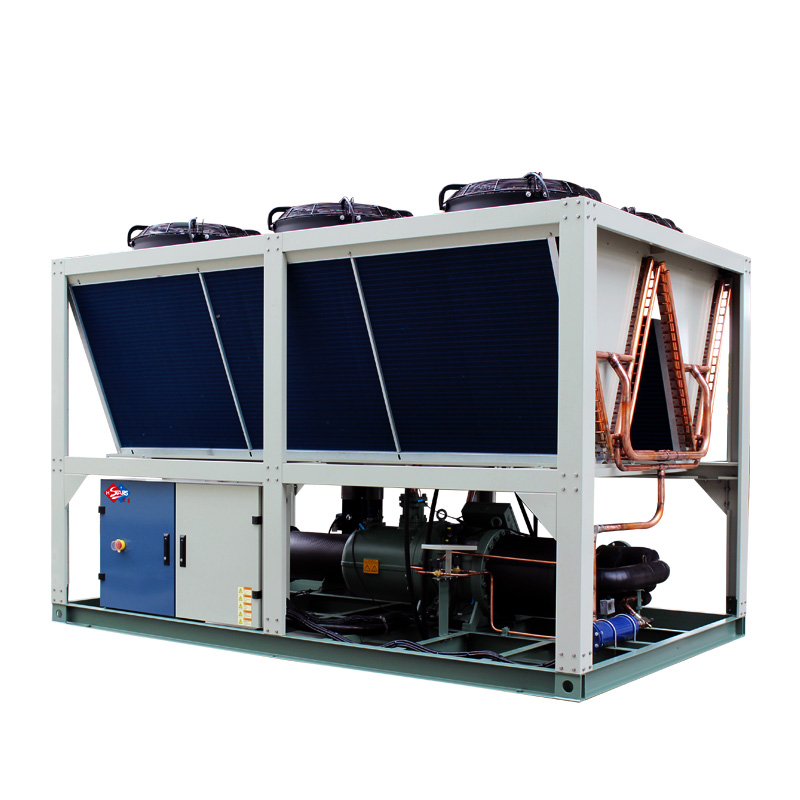

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

The low-temperature chiller can be flexibly designed in size according to the conditions of the machine room, and can be shipped in parts and assembled on site.

According to the power supply of different countries and regions, we can produce units with different power supply systems, and can also customize units and various high-voltage non-standard units according to user requirements.

According to the needs of customers, the company can provide professional advice and select more suitable equipment to make a perfect product for customers.

According to the type of refrigerant used in the project, choose heat exchange tubes and shells of different materials to avoid leakage caused by corrosion.

High temperature type: the outlet temperature of frozen water is 0℃

Low temperature type: the outlet temperature of frozen water is -20℃

Ultra-low temperature type: the outlet temperature of frozen water is -35℃

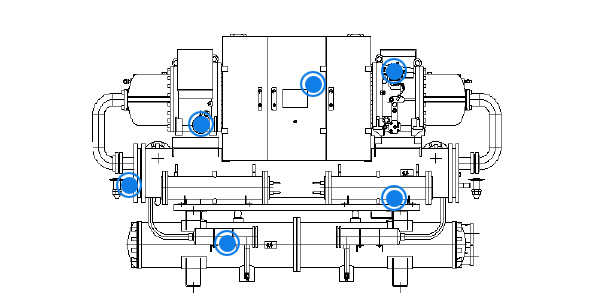

It adopts microcomputer controller, which is sensitive in response and accurate in control. It has multiple functions such as automatic loading and unloading, timing switch on and off, and recording the cause of failure and occurrence time. It can realize remote or central monitoring, and PLC controllers from famous factories are available for selection.

Unit electrical belt protection device: reverse protection, phase loss protection, compressor, fan overcurrent protection, low temperature protection, high and low pressure protection, water flow protection, etc.

The waste heat generated in the refrigeration process is recovered by using the independent technology heat recovery device. That is, while providing customers with cold water, a large amount of hot water can also be supplied free of charge.

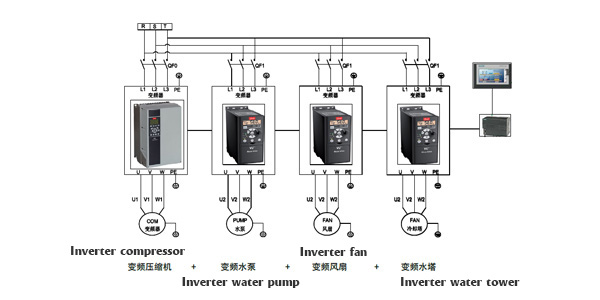

The variable frequency drive technology greatly improves the partial load energy efficiency of the unit; the evaporative cooling technology has high heat exchange efficiency, low investment and water saving

| model | Cooling capacity | input power | weight | cooling method | Refrigerant |

| 40STE-140ADSL4 | 55.4kw | 32.6kw | 1260kg | air cooling | R22 |

| 40STE-740ADSL4 | 313.0kw | 168kw | 5720kg | air cooling | R22 |

| 40STE-S140ADSL4 | 55.6kw | 40.8kw | 2140kg | air cooling | R404A |

| 40STE-S740ADSL4 | 313.6kw | 220.8kw | 1120kg | air cooling | R404A |

| 40STD-100WDSH4(high temperature) | 72kw | 22kw | 980kg | water cooling | R22 |

| 40STD-4560WDSH4(high temperature) | 3753kw | 929kw | 12000kg | water cooling | R22 |

| 40STD-S100WDSH4(high temperature) | 73kw | 26kw | 980kg | water cooling | R404A |

| 40STD-S4560WDSH4(high temperature) | 3584kw | 1191kw | 12000kg | water cooling | R404A |

| 40STD-100WDSH4(Medium and low temperature type) | 45kw | 20kw | 1070kg | water cooling | R22 |

| 40STD-4560WDTL4(Medium and low temperature type) | 2322kw | 861kw | 14000kg | water cooling | R22 |

| 40STD-S100WDSH4(Medium and low temperature type) | 47kw | 26kw | 1070kg | water cooling | R404A |

| 40STD-S4560WDTL4(Medium and low temperature type) | 2439kw | 1086kw | 14000kg | water cooling | R404A |

| 40STD-100WDSC4(Ultra low temperature type) | 18kw | 17kw | 1100kg | water cooling | R22 |

| 40STD-4560WDTC4(Ultra low temperature type) | 960kw | 772kw | 14000kg | water cooling | R22 |

| 40STD-S100WDSH4(Ultra low temperature type) | 18kw | 19kw | 1100kg | water cooling | R404A |

| 40STD-S4560WDSH4(Ultra low temperature type) | 932kw | 929kw | 14000kg | water cooling | R404A |

| ... | |||||

| Note: Only some model parameters are shown. For more model information, please contact customer serviceEmail:maychow@hstars.com.cn | |||||

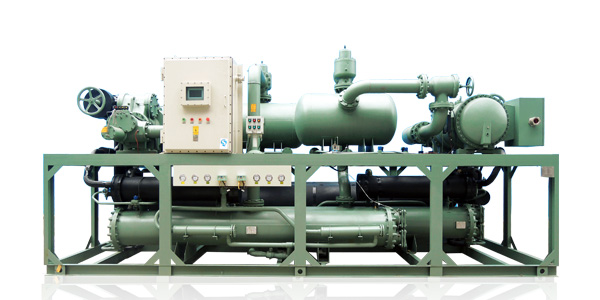

It is aimed at the explosion-proof needs of special places with flammable and explosive in the petroleum, chemical industry, coal mining industry and so on. The unit can be specially designed according to different explosion-proof grades, and the explosion-proof grade can reach: Ex dIIBT4. And provide explosion-proof certificate.

Provide professional solutions for anti-corrosion media such as sewage source, sea water source, waste gas, and waste water in the application site.

For different cases, provide professional solutions, energy saving, high energy efficiency, environmental protection and durability.

Flexible configuration of spare parts brands, professional technology, modular replacement, and strict control of details.

Special chillers with ultra-high temperature effluent and ultra-low temperature effluent can be specially designed according to the place where the equipment is used, the scene of application, and the process requirements.

Remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance.

Chat now