Industrial integ

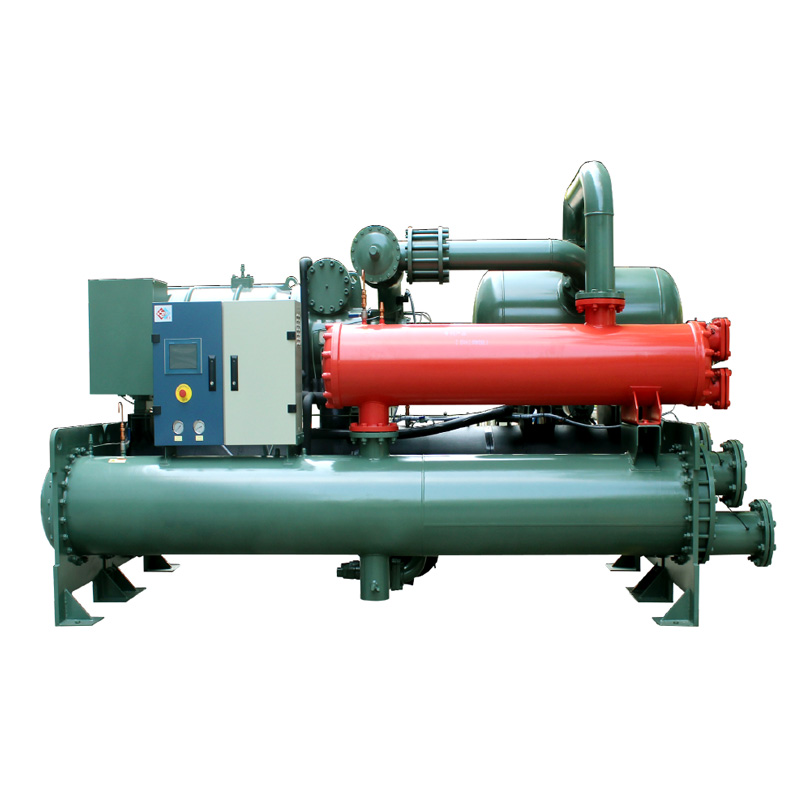

- Outlet temperature

- 5~20℃

- Refrigerant

- R22、R134a

- Cooling range

- 30kw~580kw

hot key words: Water-cooled Screw Chiller / Centrifugal Chiller / Sewage Source Heat Pump / Industrial Chiller

TEL:

The company has the production capacity of main components, owns independent intellectual property rights, adopts self-developed high-efficiency heat exchangers, and perfectly matches each component system.

The unit can be equipped with a self-developed heat recovery device, the recoverable heat is more than 30% of the cooling capacity or full heat recovery is realized, and the hot water temperature can reach 70 °C. Heat recovery does not consume energy, and the overall efficiency of the unit can be increased by 5%.

The unit has 7 kinds of safety protection measures to ensure the normal operation of the unit.

The unit is available with single and double loop designs to meet the different choices of customers. When a single compressor of a dual-circuit configuration unit fails, the other compressor can still run normally without affecting the use of customers.

The unit has passed the safety inspection before leaving the factory.

The performance of the unit conforms to the enterprise standard.

The controller adopts a highly integrated man-machine interface control center, which improves the anti-interference ability of the system。

The appearance adopts plastic shell, which is convenient for installation and maintenance.

The front and rear panels exchange data through 485 communication, and the entire system can be installed in one piece or separately.

Optional Siemens PLC controller to realize ModBus RTU, TCP or S7 communication.

The unit has been filled with refrigerant and lubricating oil before leaving the factory. Customers only need to connect the inlet and outlet pipes and power supply to operate, and the installation is simple.

| model | compressor input power | weight | Cooling capacity | Refrigerant |

| 20STB-10WS04 | 7kw | 26kg | 28kw | R22 |

| 20STB-25WDS4 | 14kw | 520kg | 70kw | R22 |

| 20STB-45WTO4 | 30kw | 1030kg | 132kw | R22 |

| 40STE-10WSO4 | 6kw | 260kg | 28kw | R407C |

| 20STB-25WDS4 | 15kw | 520kg | 70kw | R407C |

| 20STB-45WTO4 | 29kw | 1030kg | 129kw | R407C |

| 20STB-50WTO4 | 33kw | 1050kg | 150kw | R134a |

| 20STB-75WTO4 | 50kw | 1200kg | 225kw | R134a |

| 20STB-90WTO4 | 59kw | 1350kg | 270kw | R134a |

| 20STB-100WTO4 | 66kw | 1400kg | 300kw | R134a |

| ... | ||||

| Note: Only some model parameters are shown. For more model information, please contact customer serviceEmail:maychow@hstars.com.cn | ||||

It is aimed at the explosion-proof needs of special places with flammable and explosive in the petroleum, chemical industry, coal mining industry and so on. The unit can be specially designed according to different explosion-proof grades, and the explosion-proof grade can reach: Ex dIIBT4. And provide explosion-proof certificate.

Provide professional solutions for anti-corrosion media such as sewage source, sea water source, waste gas, and waste water in the application site.

For different cases, provide professional solutions, energy saving, high energy efficiency, environmental protection and durability.

Flexible configuration of spare parts brands, professional technology, modular replacement, and strict control of details.

Special chillers with ultra-high temperature effluent and ultra-low temperature effluent can be specially designed according to the place where the equipment is used, the scene of application, and the process requirements.

Remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance.

Chat now